3d printing tungsten powder is a form of tungsten that’s been specifically designed to print 3D. This powder is meticulously produced to create the design of a rounded that is why each powder chemical being excessively homogeneous and little in proportions, permitting exemplary making results.

What is tungsten powder?

Tungsten powder is an application of powdered metallic tungsten, employed as a natural product for the planning of tungsten-processed ingredients such as alloys, tungsten items and. It is just a gray-black steel with a metallic Lustre (body-centred cubic crystal). Melting point 3400. Boiling points 5555. The tungsten’s hardness is probably the most difficult of the metals. The hardest tungsten rod is 200250 and it’s the hardest tungsten rod that’s been spun after the spinning hammer moves is 350400. It’s soluble within the mix p of nitric p in addition to hydrofluoric acid. It touches in the mixture of salt hydroxide and carbonate. A little soluble in nitric p and sulfuric p in addition to aqua regia, insoluble in hydrofluoric p and water. potassium hydroxide. Tungsten has two versions A and B. At standard temperature and atmospheric force, form A is just a strong cylindrical design that is body-centered. Type W tungsten is able found in the presence of oxygen. It’s stable to 630degC, and then changes to a tungsten at temperatures above 630degC. This technique is unreversible.

Difference between tungsten powder and rounded tungsten powder

Tungsten powder and tungsten rounded powder are generally powder forms of tungsten, but they have obvious differences in morphology, chemical measurement and application.

Morphology

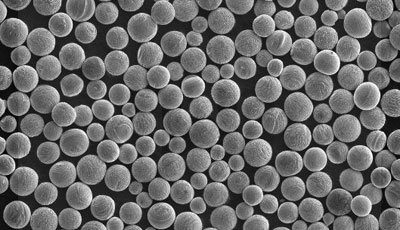

Tungsten powder is normally in granular type, while rounded tungsten powder is just a rounded powder following particular processing. This rounded form enables tungsten powder to flow and load greater in purposes such as 3D making, giving more uniform making results.

Particle Measurement

While tungsten powders have fairly large chemical shapes, rounded tungsten powders have very great chemical shapes, often in the nanometer range. This great chemical measurement enables Rounded Tungsten Dust to fit greater to the nozzle of the 3D printer, giving finer print details. At once, the great particles will also be in a position to load the print sleep, raising the density and strength of the printed part.

Applications

Tungsten powder includes a wide variety of purposes in several fields, such as light bulb manufacturing, electronics, and technical parts. In these purposes, tungsten powder is frequently used as a product or alloying element. Rounded tungsten powder, on the other hand, is specially ideal for parts such as 3D making, where it’s ready of creating more complicated, high-precision pieces and devices because exemplary flowability, filling influence and printability.

How will you make tungsten powder?

It’s made by the hydrocarbon decrease on tungsten trioxide, or ammonium paratungstate. The process of making the tungsten powder through hydrogen decrease can be divided into two levels one stage in the initial stage, at temperatures of 500-700degC, tungsten oxide is paid down to tungsten oxide; in the 2nd phase, at 700-900°C of which point tungsten dioxide will undoubtedly be paid down to the tungsten powder. The decrease response is typically executed by the shape of a tube or rotary furnace.

The efficiency of tungsten paid down powder (such as quality in addition to chemical measurement, arrangement, measurement, etc.) largely depends in the technique of reduction. Along the way of reducing tungsten in an oven pipe, the principal factors that affect the rate of decrease are temperatures of decrease, level of tungsten oxide to the burner vessel and the rate of movement that the vessel is in, in addition to the rate of flow of hydrogen, and the quantity of moisture in hydrogen. Since the temperatures of decrease, measurement of tungsten powder gets more coarse.

Production of tungsten powder along with the method of hydrogen decrease, there’s also a tungsten oxide carbon decrease practices applied at first The decrease temperature is higher than 1050 levels Celsius.The purity of the tungsten oxide powder that is produced that way is poor. More over, with the utilization of calcium, metal zinc, and many other decrease procedures of tungsten oxide research is currently underway. For unique purposes that require ultra-fine, ultrapure chemical measurement of tungsten powder the development of the tungsten chloride hydrogen decrease method The tungsten powder chemical measurement is significantly less than 0.05mm.

Industrial manufacturing may be performed through the reduced total of tungsten trioxide by hydrogen, or ammonium partungstate is handled with p and then tungsten trioxide can be made by maturation decomposition and then paid down using hydrogen.

Hydrogen decrease using tungsten trioxide hydrogen decrease can be accomplished in two measures The first stage is when tungsten trioxide heating to 550-800 , using hydrogen reduction. Another stage of decrease happens between 650 and 850 the tungsten powder is finished.

Also, it’s probable to lessen ammonium paratungstate in to blue tungsten oxide (blue tungsten) initially by hydrogen, or, if not by hydrogen then minimize it back once again to tungsten by hydrogen. The measurement and material of the tungsten powder are an important quality indicator of the tungsten powder. The decrease method is conducted via a pipe or the rotary furnace.

Rounded tungsten powder has the following advantages:

Rounded form: The rounded form enables the tungsten powder to higher load the print sleep during the making method, giving an even more uniform print result. Compared with conventional granular tungsten powder, rounded tungsten powder may greater conform to the 3D making mind and offer a better making process.

Fine chemical measurement: The great chemical measurement enables the tungsten powder to higher match to the nozzle of the 3D printer, giving finer print details. The great particles also load the print sleep greater, raising the density and strength of the printed part.

Standard chemical distribution: Standard chemical distribution decreases clogging and defects during the making method and increases print success. In conventional granular tungsten powders, the chemical distribution is normally maybe not uniform enough, which could result in clogging or defects during the making process. The uniform chemical distribution of rounded tungsten powder may successfully resolve that problem.

High purity: High-purity tungsten powder provides greater print efficiency and higher print quality. In some purposes, it’s essential to use high-purity product for making to guarantee the quality and efficiency of parts.

Rounded Tungsten Dust Software Places

Rounded tungsten powder includes a wide variety of purposes, including however not limited to the following parts:

Aerospace: Rounded tungsten powder can be used to manufacture high-performance pieces such as plane architectural parts and motor parts. In these purposes, the high strength, high density and high purity features of tungsten powder provides greater making efficiency and quality.

Automotive business: Rounded tungsten is employed for the manufacturing of pieces for automobiles, including framework pieces, motor parts and different parts. The solid durability and opposition to temperature of tungsten powder may enhance making quality and performance.

Medical area Rounded tungsten can be used to create medical devices like dental implants, medical instruments and others. The high biocompatibility in addition to the high strength of tungsten powder could enhance print quality and making performance.

Architecture: Rounded tungsten powder can be used to manufacture architectural designs and components. The high strength and wear-resistant attributes of tungsten powder provides greater making efficiency and quality.

Electronics: Rounded tungsten powder can be used to manufacture electronics, such as semiconductor devices, world boards and so on. The high thermal and electrical conductivity of tungsten powder provides greater making efficiency and quality.

It should be noted that using rounded tungsten powder for 3D making requires a particular amount of talent and experience. If you are a novice, it is advised to practice with even more accessible 3D making resources first. At once, using tungsten powder for 3D making also involves particular attention to protection, as tungsten is just a high-density steel that could simply trigger injury to the individual body. When doing so, be sure to follow the applicable protection regulations and operating procedures.